Most problems you find with scissors are that people complain that they are blunt, often you will find that the problem is that the joint is loose, on a box joint pair you can carefully hammer the joint, A box joint is where one blade passes through the other where they pivot.

I say carefully as if you do it too much you will over tighten it, place the scissors joint on an anvil or similar and carefully tap the joint frequently testing it as you go.

With an ‘X’ screw joint, that is one with a screw holding the two parts together as in the photo of the micro scissors below, try to tighten the screw till it feels right, then hammer over the thread protruding at the back, once again don’t get carried away with the hammer. It may be that the screw will not tighten, in this case simply hammer it as above but as I said carefully. If you do find that you have over tightened the joint, get some liquid metal polish, or very fine grinding powder in oil and pour some onto the instrument at the joint and the work the joint too and for a while, this should free up the joint, make sure that you clean out the joint afterwards.

The two important surfaces of the scissors are the inner facial surface and the working bevel. The intersection of these two surfaces forms the shearing edge. The bevel on the outside is called the decorative bevel and as the name suggests is merely decoration. Look at the cutting edges, and feel them, there should be a nice clean edge not rounded.

If you think that the edge is rounded you will have to take an oil stone and rub it nearly square, so that the thin edge is at an angle of between 5 and 10 degrees from a right angle with the long side of the blade, if you see what I mean.

Hold it in a vice to do it, if you only have a metal working vice with steel jaws do put in two bits of wood or aluminium to protect the steel of the scissors from being marked. You can do it with a sharpening stone or a small file.

Check that the broad side of the blade is flat and free from rust. if not you will have to rub it flat, either hold the scissors in your hand and rub the file or stone down its length or put the stone in a vice. Lubricate the stone then keeping the inside edge of the scissors flat to the stone, run it across the stone a number of times, repeat for the other blade. Very small micro scissors used in plastic surgery with a blade length of maybe 5 mm can only be done with the very finest of black Arkansas stones, even then they are difficult.

The other problem that you may come across is that after a while the tips no longer meet because the blades have been sharpened so much.

The other problem that you may come across is that after a while the tips no longer meet because the blades have been sharpened so much.

There is a cure for this, to file a little off the insides of the handles where they meet. You can also bend the handles apart slightly. It may be that the blades are misaligned because someone has used then as a lever, this is usually obvious when you look at them, this is VERY CAREFULLY put right by bending in a vice. The steel on a good pair of scissors will be quite hard so being too heavy-handed can snap the blade off.

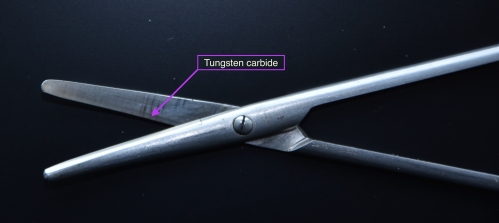

If your scissors have tungsten carbide inserts DO NOT try to bend them, Carbide will not bend so you will snap them if you try to.

A pair of tungsten carbide scissors.

It is difficult to see and therefore to photograph, but the arrow points to the Tungsten carbide inserts that are in both cutting edges. You might just be able to see then if you look closely. Also many carbide instruments will have gold coloured handle ends where your fingers hold them.

If you have a polishing wheel it is nice to polish the instrument after repair, it won’t make them work any better but they will look good. The test for a good sharp pair of scissors is that they will cut wet tissue paper or an old surgical glove without tearing. Below is a link to a good video of a scissor sharpening lesson.